Services

Strong Customer Relationships

Gear Cutting

Manufacturing Capabilities

Strong Customer Relationships

At Koro Industries, we work very hard to understand customer requirements. We take the time to communicate questions and suggestions. Economical, reliable solutions that provide maximum performance are our goal. We treat your projects as if they were our own. Our 50 + years of manufacturing experience informs your design process and helps us identify solutions should problems arise. We pride ourselves in the fact that many of our customers have come back to us time and time again for over 20, 30, 40 years and beyond. We think that’s because they know they will consistently receive a reliable, high quality product.

Bring our manufacturing expertise to your product.

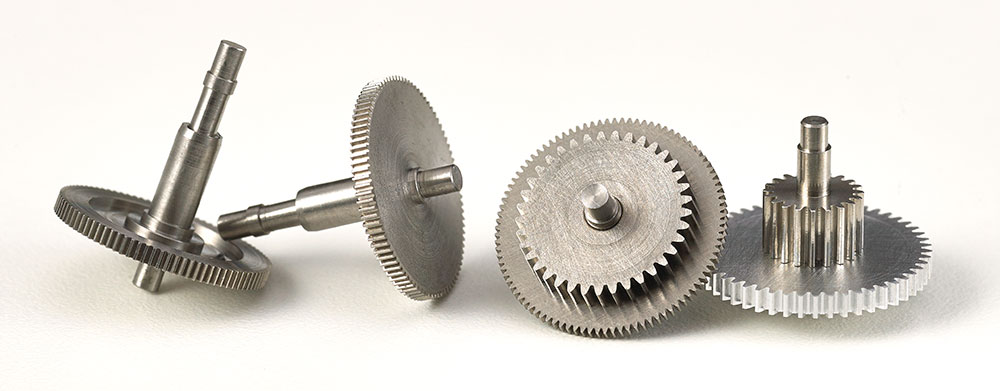

Gear Cutting and Small Assemblies

Gears are our specialty. Koro manufactures fine to medium pitch gears complete or will cut gear teeth on customer supplied blanks. See our product pages for specific capability information on bevel, helical, spur and worm type gears. Contact us with your special requirements. Koro produces prototype and small to large volume production runs of a variety of components. We manufacture and assemble small gear assemblies.

Manufacturing Capabilities

Koro manufacturing capabilities include:

- CNC Turning

- CNC Milling

- CNC Gear Cutting

- Conventional Hobbing

- Broaching

- Burnishing

- Deburring

- Precision manufacturing to AGMA and equivalent quality levels

Koro’s production capabilities focus on blanking and gear cutting small and medium pitch gears and components. Our knowledge of machining and processing methods has provided quality output for over 50 years. The integration of a “build for quality” approach into our manufacturing processes provides the foundation for stable, reliable outcomes and is “The” key element in employee training programs. We look forward to hearing from you.